Products

Product Name:EDI

Affiliate classification:

Product Profile:

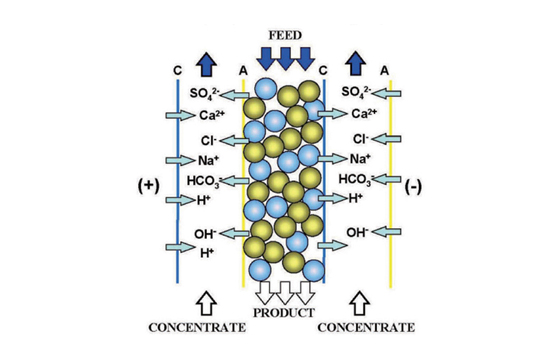

Continuous Electro-Deionization (EDI, Electro-deionization) is a method that uses mixed ion-exchange resins to adsorb anions and cations in water. At the same time, these adsorbed ions are passed through anion-cation exchange membranes and concentrated under the action of DC voltage.

Online consultationProduct Information

Product introduction

Continuous Electro-Deionization (EDI, Electro-deionization) is a method that uses mixed ion-exchange resins to adsorb anions and cations in water. At the same time, these adsorbed ions are passed through anion-cation exchange membranes and concentrated under the action of DC voltage. The electrode is removed from the water chamber. On the other hand, under the effect of DC voltage, water will dissociate to produce enough H + ions and OH- ions to achieve continuous deep desalination. This new technology can replace traditional ion exchange (DI) to produce pure water with a resistivity of up to 18MΩ. The most significant advantage of EDI is that it eliminates the need to regenerate ion exchange resins with acids and bases and is therefore more environmentally friendly.

Features

Inflow of water and concentrated / polar water countercurrent (countercurrent) to avoid scaling

Special ion exchange membrane with high exchange capacity and strong selectivity

No salt required during operation, reducing operating costs

All water chambers are fully filled with resin to improve ion migration efficiency and reduce energy

High-frequency rectifier power, rectifier effect is better than thyristor

Waterway and circuit are placed on the same side, simple and beautiful

Power Performance Overview

The current corresponds to the EDI membrane block, the working current is stable, and the voltage is better controlled.

Plug-in installation structure, plug-in input and output cables.

LED digital display, the display value is clear and clear.

The circuit breaker is used as a power switch to protectively disconnect a faulty circuit.

Input protection, output protection, soft-start current characteristic protection, over-temperature protection, flow protection.

Technical parameters of CP series EDI membrane block

Membrane performance | |||||

| Membrane block model① | CP-5800S | CP-4500S | CP-3600S | CP-2000S | CP-1000S |

| Dimensions (mm) | 616×296×810 | 616×296×615 | 616×296×515 | 616×296×405 | 616×296×315 |

| Net weight (kg) | 160 | 130 | 110 | 80 | 68 |

| Pure water flow (m3/h) | 5.0~ 6.5 | 4.0~ 5.1 | 3.0 ~ 3.8 | 2.0 ~ 2.6 | 1.0 ~ 1.5 |

| Concentrated water flow (m3/h) | 0.50 ~ 0.62 | 0.4 ~ 0.51 | 0.3 ~ 0.38 | 0.2 ~ 0.26 | 0.1 ~ 0.15 |

| Polar water flow (L/h) | 60 | ||||

| Supporting power supply model | CB-500 | CB-500 | CA-350 | CA-350 | CA-350 |

| Operating voltage (V) | 100 ~ 450 | 80 ~ 300 | 50 ~ 240 | 50 ~ 160 | 20 ~ 100 |

| Running current (A) | 0.5 ~ 5.5 | ||||

Water inlet conditions | |

| Total exchangeable anions (mg / L, as CaCO3) | ≤ 35 |

| Total hardness (mg / L, calculated as CaCO3) | ≤ 1 |

| Organic matter TOC (mg/L) | ≤ 0.5 |

| Free chlorine (mg/L) | ≤ 0.02 |

| Oxidant | 不得檢出 |

| Silica (mg/L) | ≤ 0.5 |

| SDI 15 | <1 |

| pH value | 7 ~ 9 |

| temperature (℃) | 5 ~ 35 |

| Variable metal (mg/L) | Fe≤ 0.01 Mn ≤ 0.01 |

| pressure (MPa) | ≤ 0.4 |

①Other micro-mini products, please consult the manufacturer.

|  |

| EDI works. | A power plant in Shandong: 7680m3 / d |