Products

Product Name:Outside-in Ultrafiltration(UF) Membrane Modules

Affiliate classification:

Product Profile:

Canpure external pressure membrane module has the characteristics of sufficient aeration, strong pollution resistance, strong chemical resistance, low pressure and large flux. Canpure external pressure ultrafiltration membrane can effectively reduce the turbidity of raw water, remove suspended solids, colloids, microorganisms and other substances in the water, and is highly adaptable to changes in raw water quality, simple operation and maintenance, and stable and reliable water quality.

Online consultationProduct Information

Product Introduction

Canpure external pressure membrane module has the characteristics of sufficient aeration, strong pollution resistance, strong chemical resistance, low pressure and large flux. Canpure external pressure ultrafiltration membrane can effectively reduce the turbidity of raw water, remove suspended solids, colloids, microorganisms and other substances in the water, and is highly adaptable to changes in raw water quality, simple operation and maintenance, and stable and reliable water quality.

Features

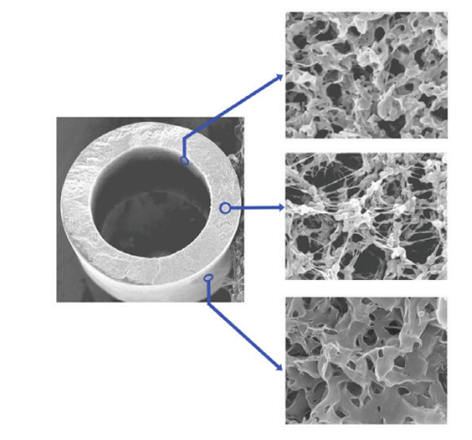

Composite thermally induced phase separation PVDF ultrafiltration membrane / patented technology /

Canpure PVDF external pressure ultrafiltration membrane is manufactured using the original composite thermally induced phase separation (c-TIPS) technology. Its membrane filament strength is greater than that of PVDF membrane prepared by the traditional immersion precipitation method (NIPS), and the filtration accuracy is higher than that of the PVDF membrane prepared by the ordinary thermally induced phase separation method (TIPS).

Permanent hydrophilicity / proprietary technology /

Canpure's external pressure ultrafiltration membrane adds hydrophilic substances and special cross-linking technology during the preparation process, so that the hydrophilicity of the membrane is permanently retained, the water flux is more stable, and the membrane's pollution resistance and cleaning recovery properties are obvious improve.

High oxidation resistance

Canpure PVDF external pressure ultrafiltration membrane has high crystallinity and can withstand higher concentrations of oxidants, so it can obtain a more thorough cleaning effect and a longer life.

High intensity and high flux

The strength of canpure external pressure ultrafiltration membrane filament is 10MPa,

The standard product water flux is 400L/m2 · h · bar, at 25℃.

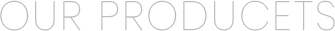

Unique aeration structure

The Canpure external pressure ultrafiltration membrane module uses a unique internal aeration device to ensure more uniform aeration and better air scrubbing effect.

Bundle integrated distribution / proprietary technology /

The canpure external pressure ultrafiltration membrane module has the most beam splitting among similar products, which effectively ensures a more uniform water flow distribution in the module.

Soft rubber root protection / proprietary technology /

The soft glue pouring technology pioneered by canpure realizes the flexible connection between the root of the membrane wire and the pouring layer, and eliminates the hidden danger of the root fracture of the membrane wire.

|  |

Schematic diagram of ultrafiltration membrane module filtration | Membrane wire section photo |

CPO series external pressure ultrafiltration membrane module technical parameters

Membrane module performance | |||||

Membrane module model | CPO-1080 | CPO-1060 | CPO-1030 | ||

Effective membrane area (m2) | 105 | 75 | 35 | ||

Membrane module size (mm) | φ250 ×2215 | φ250 ×1715 | φ250 ×965 | ||

Membrane material | Polyvinylidene fluoride (PVDF) | ||||

Film making method | c-TIPS (composite thermally induced phase separation method) | ||||

Filter pore size (μm) | 0.05① | ||||

Membrane wire inner/outer diameter (mm) | 0.7/1.3 | ||||

Housing / end cap material | UPVC | ||||

Conditions of Use | |

Filter mode | Full filtration/cross-flow filtration |

Filtration period (mins) | 20 ~ 120 |

Water production flux (L/m2·h) | 30 ~ 100 |

Backwash flux (L/m2·h) | 90 ~ 110 |

Air washing flow (Nm3/h·branch) | 5 ~ 12 |

PH tolerance range | 1 ~ 12 |

Highest NaClO tolerance concentration (mg/L) | 5000 |

Maximum tolerated turbidity (NTU) | 50 |

Maximum particle size (μm) | 300 |

Air washing pressure (MPa) | <0.1 |

Maximum water supply pressure | 0.5 |

Maximum filtration transmembrane pressure difference (MPa) | 0.2 |

Maximum backwash pressure (MPa) | 0.2 |

Operating temperature (℃) | 1 ~ 40 |

① It can be adjusted according to the raw material formula.