Products

Product Name:UF membrane

Affiliate classification:

Product Profile:

Canpure internal pressure ultrafiltration membrane has the characteristics of strong pollution resistance, high membrane filament strength and high filtration accuracy.

Online consultationProduct Information

Product introduction

Canpure internal pressure ultrafiltration membrane has the characteristics of strong pollution resistance, high membrane filament strength and high filtration accuracy. Canpure internal pressure ultrafiltration membrane can effectively reduce the turbidity of raw water, remove suspended matter, colloids, microorganisms and other substances in the water, have strong adaptability to changes in raw water quality, simple operation and maintenance, and stable and reliable water quality.

Features

Permanent hydrophilic

Canpure internal pressure ultrafiltration membrane is made of modified polysulfone (mPS) material crosslinked with hydrophilic components. The deepening and fixing of the hydrophilic groups makes the hydrophilicity of the membrane filaments permanently retained, the water production flux is more stable, and the pollution resistance and cleaning recovery of the membrane are significantly improved.

Retained molecular weight 45,000 Daltons

Canpure internal pressure ultrafiltration membrane has the lowest molecular weight cut-off and the highest filtration accuracy among similar products, which can effectively guarantee the quality of the ultrafiltration water produced.

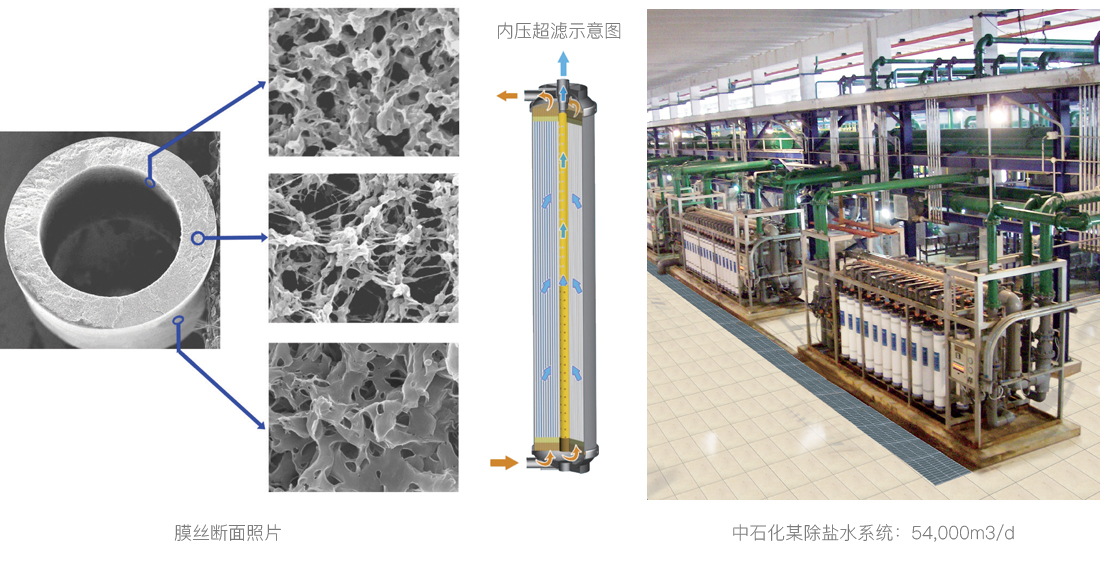

Unique membrane wire cross-section structure

Canpure internal pressure ultrafiltration membrane wire has dense sponge-like structures on both sides and a finger-like structure with low resistance in the middle, which not only guarantees the strength of the membrane wire but also has high water permeability.

High intensity and large flux

Canpure internal pressure ultrafiltration membrane wire strength 6MPa,

Standard water production flux 450L/m2?h?bar, at 25℃。

Thicker film wire inner diameter

Canpure internal pressure ultrafiltration membrane commonly uses membrane wire with an inner diameter of 1.0mm, and the cross-sectional area of the inlet channel is 1.56 times the usual 0.8mm inner diameter, which greatly improves the anti-fouling ability of the membrane module.

Beam Integrated Distribution /proprietary technology/

Canpure internal pressure ultrafiltration membrane module has the most beam splitting among similar products, effectively ensuring more uniform water flow distribution in the module。

Soft rubber root protection /proprietary technology/

The soft rubber pouring technology pioneered by canpure realizes the flexible connection between the root of the membrane wire and the casting layer, and eliminates the hidden danger of the root fracture of the membrane wire.

CPI series internal pressure ultrafiltration membrane module technical parameters

Membrane module performance | |||

| Membrane module model | CPI -1080 | CPI -1060 | CPI -1030 |

| Effective membrane area (m2) | 68 | 50 | 23 |

| Membrane module size (mm) | φ250 ×2215 | φ250 ×1715 | φ250 ×965 |

| Membrane material | Modified polysulfone (mPS) | ||

| Cut-off molecular weight (Dalton) | 45000 | ||

| Filter pore size (μm) | 0.01① | ||

| Membrane wire inner / outer diameter (mm) | 1.0/1.5 | ||

| Housing / end cap material | UPVC | ||

Conditions of Use | |

| Filter mode | 全量過濾/錯流過濾 |

| Filtration cycle (mins) | 20~ 120 |

| Water production flux (L/m2?h) | 40 ~ 130 |

| Backwash flux (L/m2?h) | 180 ~ 250 |

| pH Tolerance range | 1 ~ 13 |

| Maximum NaClO tolerance (mg / L) | 200 |

| Highest tolerable turbidity (NTU) | 20 |

| Maximum particle size (μm) | 200 |

| Maximum feed water pressure (MPa) | 0.5 |

| Highest transmembrane pressure difference (Mpa) | 0.2 |

| Backwash pressure (MPa) | 0.2 |

| Operating temperature (℃ ) | 1 ~ 40 |

①It can be adjusted according to raw material formula.