Products

Product Name:MBR curtain film

Affiliate classification:

Product Profile:

Canpure fiber reinforced membrane module has the characteristics of high strength, large flux and strong adaptability. The membrane module is immersed and placed in the membrane tank, with high system integration and good water quality. Canpure fiber reinforced MBR membrane modules are suitable for municipal/industrial sewage treatment, high-concentration organic wastewater treatment and other fields.

Online consultationProduct Information

Features

high strength

Canpure fiber reinforced membrane is a PVDF membrane with a support layer. The membrane filament has high strength and can effectively avoid the problem of hollow fiber membrane filament breakage.

No peeling

Canpure's proprietary thermal inlay technology makes the PVDF membrane and the fiber braided tube tightly integrated, and no peeling occurs during operation.

High operating flux and small filter pressure difference

Canpure's proprietary membrane technology can ensure that the filter skin is evenly coated on the support layer of the fiber braided tube, and can achieve uniform pore size and high opening rate. High operating flux, effectively reducing the filtration pressure difference.

Strong adaptability to raw water

Canpure fiber-reinforced membrane is highly adaptable to the raw water quality, and works well under the condition of large fluctuations in raw water quality and temperature. It is suitable for surface water, groundwater treatment, reclaimed water reuse, sewage treatment and other fields.

Tolerate high-intensity air scrubbing and water washing

Canpure fiber-reinforced membrane can withstand high-strength air scrubbing and water washing, which can effectively avoid the problem of sludge accumulation in the membrane module.

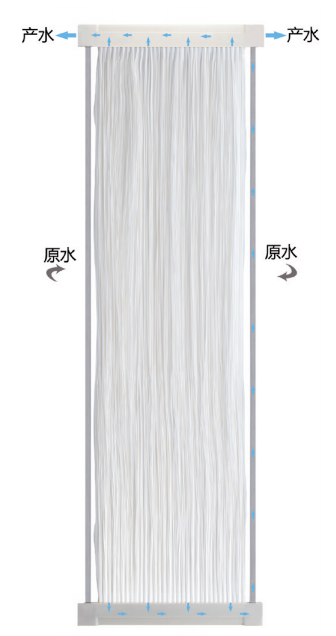

Water production at both ends

Canpure fiber-reinforced membrane module adopts the water production method at the upper and lower ends, which has a larger flux than the traditional single-ended water production membrane module, uniform pollution load distribution, and can effectively reduce the transmembrane pressure difference and extend the operation cycle.

|  |

Filter diagram | Membrane wire section photo |

CPES /CPEM series membrane module technical parameters

Membrane module performance | |||||

Membrane module model | CPEM-2540 | CPEM-2580 | CPEM-5080 | ||

Effective membrane area (m2) | 8.9 | 20 | 40 | ||

Membrane module size (mm) | 625*1000*30 | 625*2000*30 | 1250*2000*30 | ||

Membrane material | Polyvinylidene fluoride (PVDF) | ||||

Membrane form | Reinforced hollow fiber membrane | ||||

Filter pore size (μm) | 0.1① | ||||

Membrane wire outer diameter (mm) | 2.0 | ||||

Conditions of Use | |

Filter mode | Gravity/suction filtration |

Filtration period (mins) | 20 ~ 120 |

Water production flux (L/m2·h) | 5 ~ 60 |

Aeration flow (Nm3/h·curtain) | 1 ~ 3② |

pH tolerance range | 1 ~ 12 |

① It can be adjusted according to the raw material formula. ②Using 5080 membrane curtain, the air volume is doubled. ③In addition, the outer diameter of the membrane wire is 2.6mm, 1.6mm products are available for selection, please consult the manufacturer for specific details.